- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-05-17 Origin: Site

Solar energy has become a cornerstone of the global shift toward renewable energy, with solar panels being widely deployed in residential, commercial, and utility-scale applications. A typical solar panel consists of several critical components: photovoltaic (PV) cells that convert sunlight into electricity, glass covers that protect these cells, encapsulants that seal and cushion the cells, and backing sheets that provide structural support and environmental protection.

Among these components, the backing sheet plays a vital role in ensuring the panel’s durability, longevity, and performance. It acts as the final protective layer on the rear side of the solar module, shielding sensitive elements from moisture, mechanical damage, UV radiation, and temperature fluctuations.

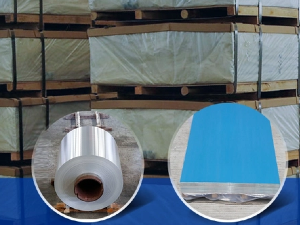

A key material choice for backing sheets is coated aluminium coil. Thanks to its unique combination of strength, lightweight, corrosion resistance, and adaptability to coatings, coated aluminium coil offers superior protection and functionality in solar panel assemblies.

Before diving into the specifics of coated aluminium coils, it is important to understand the solar panel’s structure. Most panels consist of several layers arranged from front to back as follows:

Glass Cover: A tempered glass layer that protects the PV cells while allowing sunlight to pass through.

Encapsulant: Usually made from ethylene-vinyl acetate (EVA), this layer cushions and seals the PV cells.

Photovoltaic Cells: Silicon-based cells that convert solar energy into electrical power.

Backing Sheet: The rear layer that provides mechanical support, insulation, and protection against environmental hazards.

The backing sheet must meet demanding requirements: it needs to be electrically insulating to prevent short circuits, resistant to UV radiation and moisture ingress, mechanically robust to withstand thermal expansion and weathering, and compatible with lamination processes. Choosing the right material for backing sheets is crucial to achieving long-lasting solar panels.

Aluminium is an ideal base material for backing sheets due to several intrinsic properties:

Aluminium exhibits excellent thermal conductivity, which helps dissipate heat generated within solar panels. Efficient heat management improves the panel’s electrical performance and reduces the risk of hotspots that can degrade PV cells over time. Moreover, aluminium’s structural rigidity ensures that backing sheets maintain their shape and resist mechanical stresses during installation and operation.

Weight is a critical factor in solar installations, especially for rooftop and large-scale solar farms. Heavy panels increase installation costs, require stronger mounting systems, and may impose limitations on building structures. Aluminium’s lightweight nature significantly reduces these challenges. When using coated aluminium coil for backing sheets, manufacturers benefit from both the inherent lightness of aluminium and the protective coatings that enhance durability without adding excessive weight.

The coatings applied to coated aluminium coils are fundamental to their effectiveness and success as backing sheet materials in solar panels. These coatings provide a range of critical performance benefits that ensure the long-term durability, safety, and efficiency of solar modules.

Solar panels are exposed to intense sunlight and harsh environmental conditions for decades. UV radiation, in particular, can cause significant damage if the materials are not properly protected. Specialized coatings on coated aluminium coils act as a protective shield against UV degradation, preventing common issues such as color fading, chalking, and brittleness of the aluminium substrate. This protection helps maintain the aesthetic appearance and structural integrity of the backing sheets over time.

Beyond UV resistance, these coatings also offer excellent weatherability. They provide robust defense against rain, hail, strong winds, and wide temperature fluctuations—from scorching heat to freezing cold—ensuring that the coated aluminium coil backing sheets remain intact and functional throughout the solar panel’s expected lifespan, often 25 years or more. This weatherproof quality is crucial for panels installed in diverse climates, from sunny deserts to coastal or cold regions.

While aluminium naturally exhibits good corrosion resistance, environmental factors such as moisture, salt spray (especially in coastal areas), industrial pollutants, and acidic rain can accelerate corrosion over time. The coatings on coated aluminium coils create an additional, highly effective barrier that prevents these corrosive agents from reaching the metal surface. This barrier is vital to maintaining the mechanical strength and protective properties of the backing sheets, preventing rust or degradation that could compromise the panel’s safety and longevity.

Moreover, the coatings contribute significantly to the electrical insulation properties of the backing sheet. Since solar panels operate with high voltage, electrical insulation is critical to preventing short circuits and ensuring safe, reliable operation. The coating layer helps isolate electrical components and reduce risks associated with electrical faults, protecting both the panel and end users.

In addition to protection, coatings on coated aluminium coil backing sheets are often engineered to control reflectivity. This feature can improve the overall energy efficiency of solar panels in several ways. Some coatings optimize light reflectance by reflecting stray light back into the solar cells, enhancing the amount of energy converted. This can contribute to slightly higher power output without increasing panel size.

In urban or residential settings, coatings that reduce glare are highly valuable. Glare reduction helps minimize visual disturbance to neighbors and passersby, making solar installations more community-friendly and compliant with local regulations.

Solar technology has evolved into different types, with crystalline silicon (c-Si) and thin-film modules being the most common. The backing sheet must be compatible with these diverse technologies and their specific assembly methods.

Coated aluminium coil backing sheets are widely used in both c-Si and thin-film solar modules. For crystalline silicon modules, which dominate the market, aluminium backing sheets offer a balance of mechanical strength and environmental protection. Thin-film modules, which often require flexible or specialized substrates, also benefit from aluminium’s adaptability when combined with advanced coatings.

Solar panels come in various structural formats, including glass-glass and glass-film laminations. Coated aluminium coils can be engineered to work effectively in these different assemblies. The coatings facilitate strong bonding with encapsulants and provide a stable substrate that supports the lamination process, preventing issues like delamination or warping.

The manufacturing process for solar panels demands precise material characteristics to ensure quality and reliability.

Effective adhesion between the backing sheet and encapsulant is essential for the panel’s durability and moisture resistance. Coated aluminium coils are designed to have surface chemistries and textures that promote strong bonding with encapsulants such as EVA, which is widely used in the solar industry. This secure bonding prevents moisture ingress and mechanical separation over time.

Consistent surface flatness and tight thickness tolerances are crucial during lamination to avoid stresses that could cause cracking or delamination. High-quality coated aluminium coils are manufactured with strict control over these parameters, ensuring that the backing sheets provide a smooth, uniform surface for reliable panel assembly.

Solar panels are expected to perform reliably for 25–30 years or more, often backed by long-term manufacturer warranties. The choice of backing sheet material, including coated aluminium coil, directly influences this lifespan.

Coated aluminium coils deliver excellent durability throughout typical solar panel lifecycles. Their corrosion resistance, thermal stability, and mechanical strength ensure that backing sheets maintain their protective functions under prolonged exposure to weather and UV radiation.

Delamination, cracking, and mechanical failure of backing sheets can lead to panel malfunction or failure. Coated aluminium coil’s compatibility with encapsulants and its resilient coatings reduce the risk of such issues, supporting warranty commitments and reducing maintenance costs.

Coated aluminium coils are essential to enhancing the performance, durability, and reliability of solar panel backing sheets. Their unique combination of lightweight strength, excellent thermal conductivity, superior corrosion resistance, and advanced coating technology makes them perfectly suited to meet the demanding conditions of solar installations. With the global solar energy market growing rapidly, the need for high-quality coated aluminium coil backing sheets is stronger than ever, driven by the push for longer-lasting, more efficient, and eco-friendly solar panels.

For manufacturers and suppliers seeking cutting-edge coated aluminium coil solutions that comply with stringent performance and warranty standards, Guangdong Guangyun New Material Co., Ltd. stands out as a trusted partner. Their expertise and innovative products are designed to support the evolving needs of the solar industry, helping you deliver reliable, high-performance solar panels. To learn more or discuss tailored solutions, we highly recommend contacting Guangdong Guangyun New Material Co., Ltd. for professional guidance and quality materials.